Decra®’s material structure consists of 8 layers of perfection, as we call it. Steel is only one layer. There are other vital components that contribute to the unique benefits that makes Decra® so special. What are those layers?

If we could condense the DNA of Decra® in one catchy slogan it would be:

Feel the steel.

The Steel is the heart of the Decra® tile and provides it with its strength, rigidity and light weight.

Steel makes our product stand out among conventional roofing products.

However, steel is still only one layer. There are other vital components that contribute to the unique benefits that makes Decra® so special.

What are those layers?

First let’s talk about steel. You see, we would like you to feel the steel!

Decra®’S SUPER-POWER: THE ZM250 STEEL

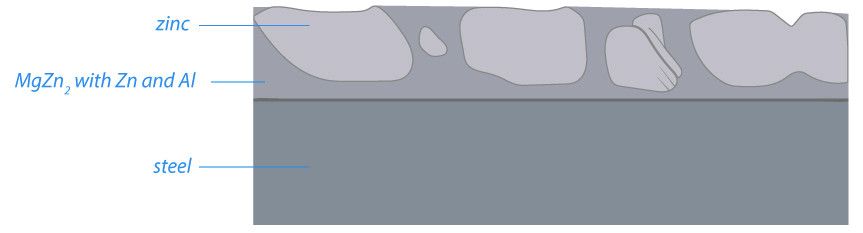

Decra® tiles are made with strong ZM250 steel, which is special because it’s protected on both sides with zinc-aluminium-magnesium alloy.

That double layer of protection makes the tiles resistant to any physical damage and provides excellent protection against weather conditions. The unique alloy composition of ZM 250 with optimal balance between zinc, aluminium and magnesium, provides superior corrosion resistance by combining the sacrificial protection of zinc with the bariedr protection of aluminum and magnesium.

All tests show that ZM 250 systems provide better corrosion protection than other metallic coating systems (for example, at least twice as good as regular Hot Dip Galvanized steel). Thanks to its 3% magnesium content, ZM250 steel offers self-healing on cut edges. Both sides of the zinc-magnezium alloy coated steel are protected with a polyurethane layer that provides protection and a uniform substrate for further coatings.

In our manufacturing process the tiles are pressed first before the textured or paint coating is applied and then baked, which contibutes significantly to the durability of the tiles coating.

Decra®’S SUPERGLUE: THE BASECOAT

In case of stone chip coated tiles, such as Decra® Classic, Stratos L and Oberon,

the chips are bonded to the tile by means of the coloured basecoat. It serves two main purposes:

It has also good UV resistance and retains its flexibility although it does become harder after the first few weeks.

Decra®’S STYLISH DESIGNER: THE STONE CHIPS

That’s the reason Decra® looks gorgeous unlike many other cheap looking metal roofs. You can’t tell that it isn’t a stunning clay roof!

To provide this attractive textured finish and at the same time enhance resistance to UV radiation, a layer of carefully selected stone granules is applied to the tiles The granules are ceramic coated with lightfast heat resistant pigments.

But stone coating isn’t the only way to make Decra® look irresistable!

POWDER COATED FINISH. THAT MAKES Decra® PROFILES ELEGANCE AND QUBE LOOK LIKE A SLEEK SPORTSCAR

These products are finished with a Super Durable, stylish, scratch resistant powder coating, with Ultra UV resistant surface coating. After tiles have been pressed, a Super Durable 80-micron polyester powder coating, heated to high temperature, is then backed to the tile. This process of coating and baking after pressing ensures a continuous, even coating and prevents micro-cracking that can occur in the bends of steel roof products that are painted first and then pressed or rolled into shape.This process gives the Decra® Elegance and Qube a critical advantage over standard panels that are pre-coated with a significantly thinner 20-30 micron coating layer.

THE MAGNETIC FORCE OF SHINY OBJECTS: THE OVERGLAZE

The final touch on a Decra® tile is provided by the clear acrylic overglaze. It makes the whole tile look elegant. No, it does more than that. It makes every single Decra® tile look perfect.

It sounds about right because only then we can call Decra®’s secret sauce the 8 layers of perfection.